Truss structures, commonly referred to as “trusses” or “American-style trusses”, are a key element in setting up stages for events, concerts, and theatrical productions. In Italy, the term “americana” is widely used to describe modular truss systems, usually made of aluminum, designed to support lighting, audio equipment, or scenic elements. In this article, we’ll review their main characteristics, explain how to choose the right system, and explore the details that set a professional truss apart from a standard one.

Many of you have probably wondered why modular truss systems for stages are called “American-style trusses.” The reason is actually quite simple. In the 1970s and ‘80s, some of the most advanced stage technology, such as modular aluminum trusses, was being imported from the United States. These structures were very different from the heavier, less flexible, and harder-to-assemble traditional systems used in Italy at the time. To describe these lightweight, modular, and easy-to-assemble systems, the term “americana” began to be used. Over time, it became part of the technical jargon in Italy and is still commonly used today to refer to these structures, which are essential for safely supporting lights, audio equipment, LED walls, and other scenic elements above or beside the stage.

While trusses are primarily used for concerts and live performances, they’re also widely used in trade shows, exhibitions, and fairs to build portals or load-bearing structures.

With that introduction, let’s take a look at the various types available.

Structures, profiles, and materials

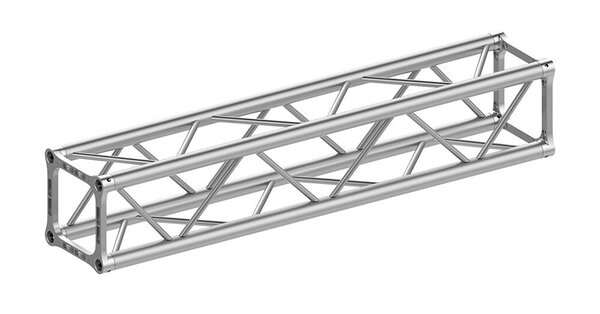

Built from aluminum due to its light weight and strength, trusses consist of modular elements that can be combined to create complex and customized configurations.

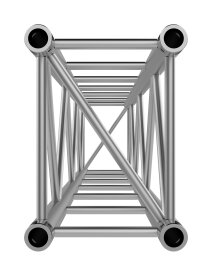

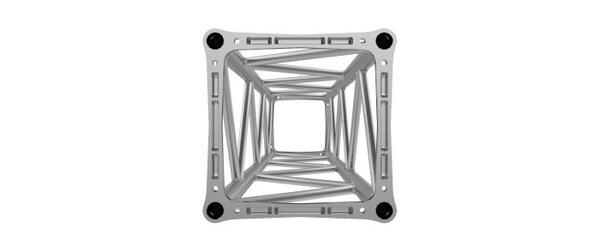

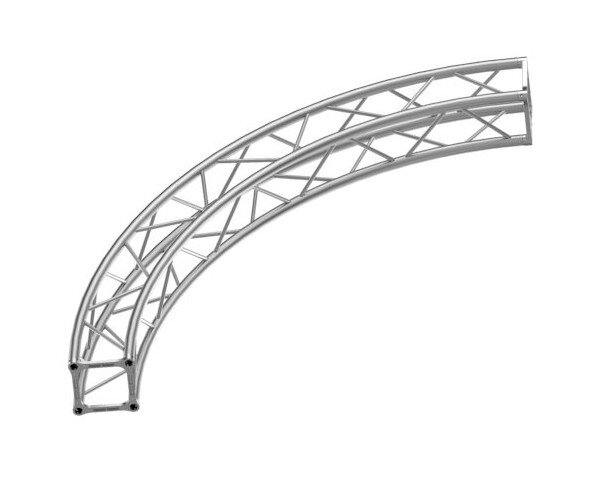

Trusses come in various shapes—flat (also called ladder), triangular, square, or rectangular—each with different load capacities, lengths, and formats. The most common configurations are straight, angled, or circular. The standard tube diameter is 50 mm.

The image below shows the cross-sections available in the Trabes P series trusses (with plate) and the B series (rectangular profile):

Trusses with plates offer the advantage of being directly bolted to a surface (such as a wall) without the need for additional mounting plates.

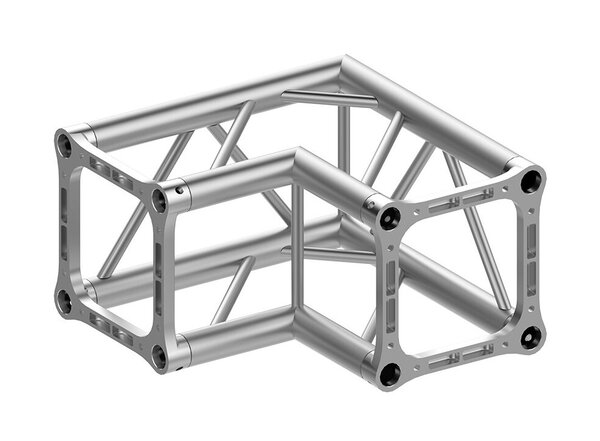

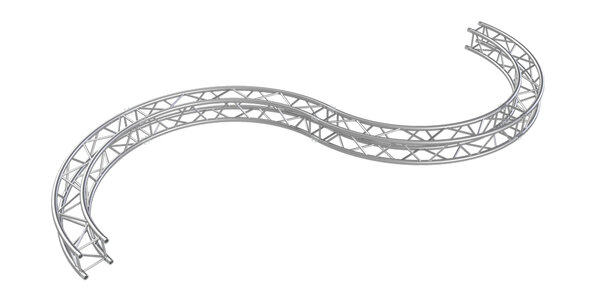

In terms of shape, the most common formats are straight, angled, or curved—allowing you to create circular or wave-shaped structures:

All shapes are naturally available in flat, triangular, square, etc., cross-sections.

The angled truss is worth a closer look, as the market offers a wide variety of angle connectors—ranging from acute to obtuse, with upward or downward orientation. In addition to angled connectors, you’ll also find 4- and 5-way junctions that allow multiple trusses to be joined at a single point for particularly elaborate setups.

Between the main 50 mm tubes of each truss, smaller tubes are welded to create a reinforcing and stiffening system based on the classic triangular lattice structure—one of the oldest and most reliable designs in structural engineering, used for centuries.

Typical truss sizes are based on 22 cm or 29 cm spacing, though larger ones (such as 40 cm spacing) are also available. The 22 cm trusses are mostly used for decorative rather than structural purposes, and are often called “deco trusses.” They’re commonly found in exhibitions, showrooms, corporate events, art installations, or as architectural features in venues and clubs.

Heavy-duty trusses, on the other hand, are designed for very high loads and long spans, making them ideal for large-scale events, main stages, roof systems, and permanent installations.

As previously mentioned, truss lengths are based on 50 cm increments, 50, 100, 150, 200, 250 cm, and so on, up to 4 meters (or 6 meters for heavy-duty models). For longer lengths, it’s generally preferable to assemble multiple modules for reasons of transport, safety, and flexibility. Special-length spacers are also available for custom sizing beyond the standard dimensions.

Truss length is an important factor to consider. While a 200 cm segment may cost less than two 100 cm ones, longer trusses can be more difficult to transport and maneuver.

Finally, trusses are available not only in raw aluminum finish but also in matte black or white. Some manufacturers offer custom paint finishes upon request ideal for exhibitions or scenic applications—and even special coatings such as corten-effect or metallic-look finishes.

Connectors and accessories that make the difference

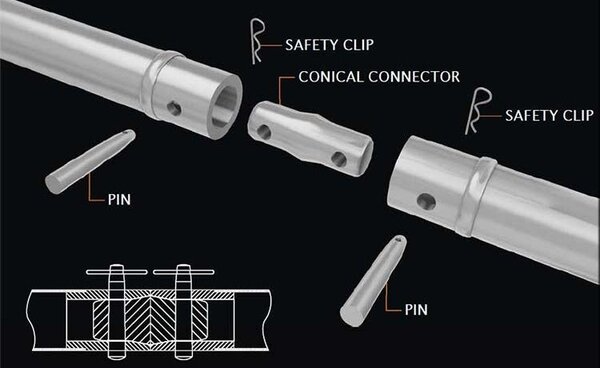

The truss modules are joined together using special connectors called spigots (also known as “eggs”), which are double cones inserted into the 50 mm tubes and locked in place with pins and safety clips.

There are also base plates, spacers, clamps (essential for attaching lights, speakers, or other equipment to the truss), and everything needed for a complete setup.

Naturally, there’s a wide range of accessories available to handle every situation—from stretch PVC covers to outriggers, extensions, and adapters for connecting different truss sections or creating custom angles and curves. Adjustable brackets allow you to mount video projectors, LED walls, or monitors directly onto the truss, and safety cables are essential. Italian safety regulations require that every object hung from a truss must be secured with an approved steel safety cable.

Safety and quality first

In today’s market, not all trusses are created equal. When working with load-bearing structures designed to hold several tons of equipment, quality is not optional—it’s essential. The difference between a budget truss and a professional-grade product lies in critical details: the thickness of the aluminum, the precision of the welds, the accuracy of the connectors, and the reliability of the materials used.

A standout example of Italian manufacturing excellence is Trabes trusses, produced by Unirig and distributed by Audio Effetti. Their philosophy is built around quality, safety, and attention to detail. Every component is carefully engineered, made from selected materials, and subjected to strict quality checks throughout the production process.

Certification is another crucial factor. These are provided directly by the manufacturer and specify the load capacity and physical characteristics of each module.

Lastly, remember that a structure’s safety depends not only on the product itself but also on correct assembly and final inspection of the installed configuration.

Relying on trusted brands and qualified technicians means ensuring not only top performance but, above all, safety. And when the curtain rises, that’s the first and most important requirement—one that should always be silently guaranteed.

Wanto to learn more?

Email us at international@audioeffetti.it

English

English  French

French