Load cells are essential devices for monitoring the stability of truss structures used in any type of show. Though invisible to the eye, they are vital guarantors of safety for thousands of people, as real-time measurement of applied forces ensures full control of the stability of suspended or ground-supported structures. In a field where every extra or missing kilogram matters, these devices are therefore indispensable for technicians, riggers, and designers.

In the world of live events, but not only, safety is never optional. Truss structures, commonly referred to as “trusses,” are at the heart of stage setups, as they support audio systems, lighting, LED walls, and complex scenic elements weighing several tons. Yet every suspended element represents a potential risk if not correctly assembled and monitored. This is precisely the role of load cells: they are sensors that measure the force applied at a specific point on the structure. They enable real-time verification of load distribution, preventing structural failures.

They can be considered the technological evolution of spring dynamometers, but with far superior precision, versatility, and reliability. Both rely on the same physical principle: an applied force produces a measurable deformation. While in dynamometers this was expressed through the extension (or compression) of a spring and subsequently read in an “analog” manner, in modern load cells the deformation is microscopic and detected by strain gauges bonded to a metal body. These convert the change in length into an electrical signal, which can then be processed for the intended application.

Types of load cells for rigging and truss structures

The load cells used in our industry differ in shape, operating principle, installation method, and signal type. They range in capacity from 250 kg to 20 tons, depending on the model and application (trade shows or large stages/structures). They are manufactured in stainless steel, anodized aluminum, or galvanized steel, with an IP65 protection rating (or higher) for outdoor use. Naturally, they all feature the required certifications: CE, RoHS, etc.

The most common types are:

- Shackle load cells, integrated into lifting shackles, for direct monitoring at suspension points:

As mentioned earlier, these cells work on the principle of elastic deformation: a strain gauge embedded inside the shackle’s metal body measures microscopic shape variations caused by the applied load. These variations are converted into an electrical signal proportional to the weight or force exerted. For example, in the Flexa Sensors XFW-CSH475B1 model, the wireless electronic unit (housed in the small cylinder next to the shackle) transmits real-time data to a receiver and then to monitoring software, while also containing the battery for operation.

- Load link / dynacell models, shaped like a bar with eyelets:

These cells, suitable for heavy loads, are typically placed between a hoist and the structure, but not exclusively. For instance, the ultracompact Flexa Sensors XFW-CDY500H2 fits a wide range of rigging systems. The load link configuration ensures absolute load accuracy.

- Compression load cells, designed to measure vertical loads on surfaces such as stages and towers. They are intended for static loads and provide high precision.

In practice, compression load cells operate like high-capacity industrial scales: they detect pressures or static loads acting from top to bottom, often ranging from hundreds of kilograms to several tons.

Flexa Sensors also produces specialized variants of compression load cells, such as the Truss Smart Pin models, which are installed at the base of towers or at truss junctions. Compared to traditional compression models, these are also suitable for dynamic loads.

- Beam load cells, which measure bending deformation. They are cost-effective and versatile.

Flexa Sensors wireless load cells

In the world of structural setups for events, we have seen how crucial it is to know the actual load applied to each suspension point. Flexa Sensors, an Italian brand specializing in sensor systems for measuring suspended loads and part of the Area Four Industries Italia group, addresses this need with two technological platforms designed for different scenarios.

- Real-Time: Immediate Control for Live Rigging

The Real-Time system is the ideal choice for those working on stages, delay towers, trusses, and temporary structures. Data is updated every second, providing an instant overview of each cell’s status: normal, overloaded, or underloaded.

How does it work? Dedicated software, installed on a computer (Mac or Windows) and connected to gateways via a USB-A cable, communicates wirelessly with the load cells to measure the suspended load. This software can also operate in “offline” mode, i.e., without any connected load cells.

Advantages:

- Local monitoring with PC and gateway

- Up to 100 wireless cells managed simultaneously

- Drag & drop interface on rigging plot

- Compatibility with EXE RISE hoists (load cell integrated into the hook)

- Fully wireless communication

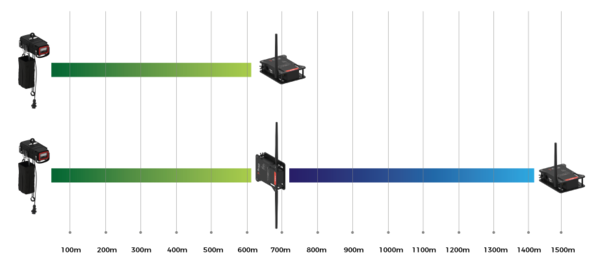

The Real-Time family includes shackle cells, DynaCells (with a safety factor of 8:1 and maximum loads of 500 kg or 5 tons), and a load cell integrated directly into the hoist hook—what could be defined as an “embedded” model. All three can be used simultaneously within a single setup. If the gateway coverage needs to exceed 500 m, a Repeater can extend it to approximately 1,500 m.

- IoT: Distributed Monitoring for Large Structures

The IoT line is designed for large environments such as exhibition halls, convention centers, and permanent installations. Based on the LoRaWAN protocol, it allows monitoring of hundreds or even thousands of cells with updates every 3 minutes.

Advantages:- Remote access from multiple devices via cloud

- Management of up to 1,000 cells per system

- Mobile app for QR scanning and configuration

- Indoor/outdoor gateway with coverage > 1,000 m

- Compact, lightweight design (only 300 g)

There is also a third platform, based on the LC-NLP system: a wired solution for instant control and automatic response in case of anomalies. Integrated with EXE DRIVE DL controllers, it can cut power to hoists in the event of overload.

English

English  French

French