In professional video installations, the demand for reliable floor-mounted LED wall solutions continues to grow steadily. Corporate events, museums, showrooms, trade shows, and permanent installations all require robust, dependable structures that are versatile, easy to assemble, and compatible with a wide range of LED cabinets. Within this landscape, the VMB LWS (LED Wall Support) series stands out as one of the most complete and intelligently engineered solutions currently available designed to simplify installers’ workflow while ensuring high performance in every environment.

As is well known, stacked supports are self-supporting structures designed to install an LED wall directly on the floor when suspended solutions are not feasible. They are based on the principle of “stacking” (hence the term), building the wall from the ground up to ensure stability, modularity, and fast assembly. However, not all systems of this type are created equal: many are proprietary, lack flexibility, or require brand-specific adapters for each LED cabinet.

The LWS series was developed precisely to overcome these limitations, delivering a truly universal, modular system engineered for long-term durability.

The system is manufactured by VMB, the long-established international brand through which the Spanish company Prolifts markets its products. Audio Effetti is the official distributor for the Italian market. Prolifts brings over thirty years of experience in the design and manufacturing of tower lifts, trussing, and rigging systems for the professional audio and video industry.

A universal system designed for professionals

The ladders are installed onto a robust steel base composed of a front section with adjustable stabilizers available in two widths (LW-B05, 50 cm, and LW-B1, 1 m) and a rear section (LW-B2) equipped with a leveling spindle, allowing floor irregularities to be compensated with maximum precision. The two sections are arranged orthogonally to each other.

Multiple aligned bases can be securely joined together using dedicated connection bars (LW-U), simply fastened with screws.

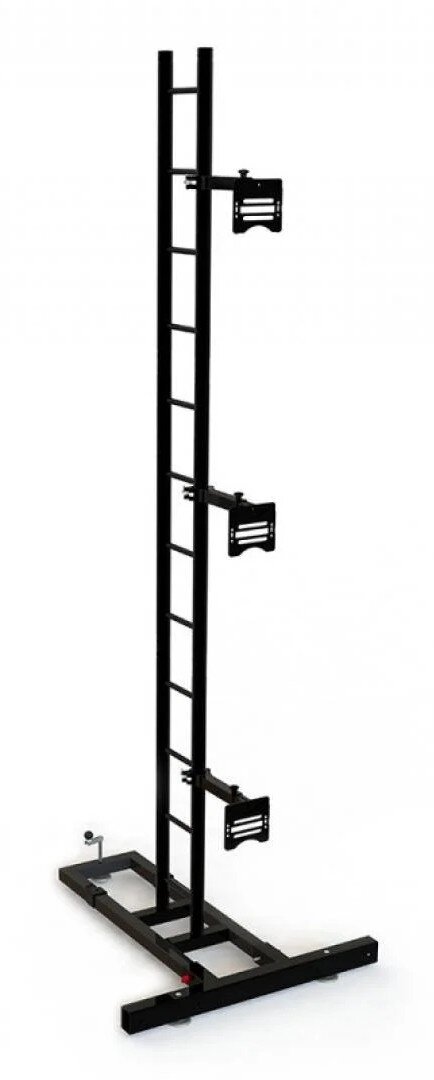

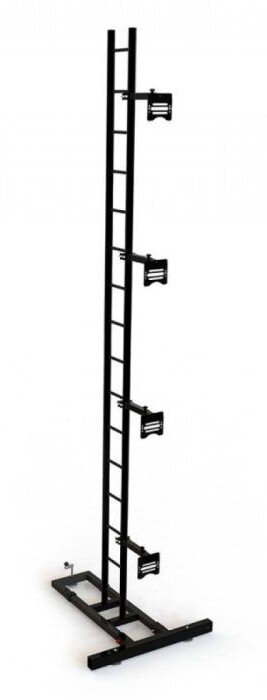

Once the base has been positioned and leveled, the ladders are mounted onto their designated supports via a quick-lock system featuring conical pins and safety clips, ensuring fast and secure assembly.

The ladder columns—formed by placing multiple bases side by side—are interconnected using dedicated safety arms, LW-AR2 (extendable) and LW-AR3, providing additional structural stability.

The LED wall is then installed panel by panel using the LW-AR1 extendable arm (which attaches directly to the ladders) together with a universal mounting plate compatible with the majority of LED cabinets currently available on the market.

Each plate is designed to support and secure up to four cabinets, ensuring both stability and installation efficiency.

This feature makes the system particularly attractive for rental companies, as it can be used with different LED brands without the need for dedicated adapters.

What we have described may sound more complex than it actually is. In practice, one of the key strengths of the LWS system is its ease of assembly. The entire process has been engineered to be fast and intuitive, reducing installation time and minimizing the need for specialized personnel.

That said, assembling the system with two operators is always recommended.

Accessories and advanced configurations

To further enhance stability and safety, VMB offers a comprehensive range of accessories. In addition to front and rear stabilizers and safety arms, the lineup includes dedicated counterweight supports.

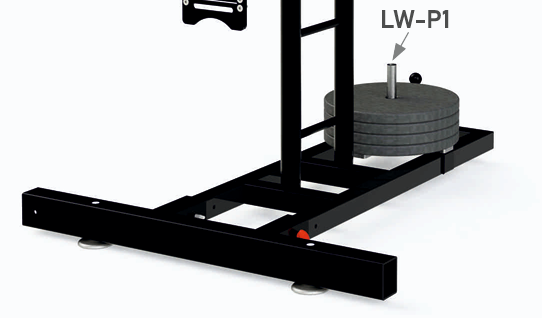

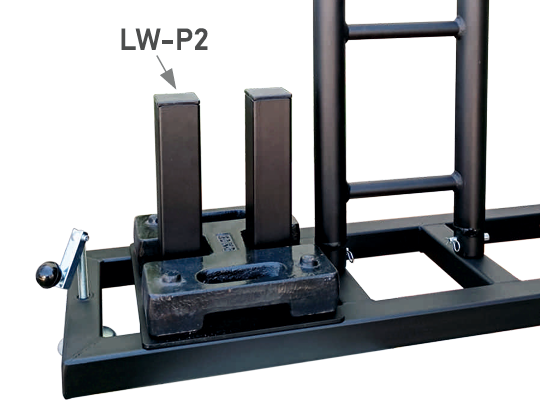

These deserve a closer look: the LW-P1 is a 25 mm diameter bar designed for cylindrical counterweights, positioned at the end of the base to increase stability. The LW-P2, on the other hand, is designed to accommodate standard 20 kg counterweights (CWA-20), commonly used in gym equipment. This solution allows users to accurately determine and adjust the exact amount of counterweight required for the structure.

Below is the LW-P1 solution with cylindrical counterweights, shown from the rear:

These components allow for single, double, or multiple configurations while consistently maintaining high structural rigidity.

The system’s modular design also makes it possible to create structures of varying heights and widths, perfectly adapting to the requirements of live events, museum installations, or corporate applications.

Four preconfigured systems

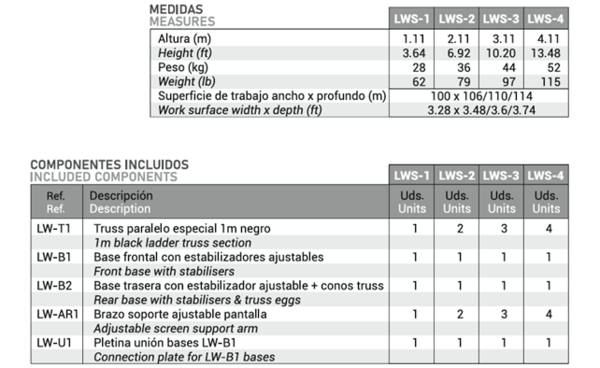

VMB offers four different preconfigured systems, which vary in height and in the number of support arms included: LWS-1, LWS-2, LWS-3, and LWS-4.

All configurations use the 1 m ladder sections (LW-T1). By connecting multiple sections together, different overall heights can be achieved. Naturally, taller structures require a greater number of LW-AR1 support arms (up to four).

Below is the table outlining dimensions and individual components, as specified in the corresponding datasheet:

Why choose VMB LWS: tangible advantages

The LWS series combines a range of features that set it apart from many competing solutions. Its near-universal compatibility with LED panel cabinets across virtually all major brands eliminates the need for proprietary systems, while its intelligent modular design reduces warehouse costs and simplifies logistics. The build quality based on powder-coated steel and aluminum ensures long-term durability and resistance, even in demanding, high-frequency applications such as rental and live production environments.

From an operational standpoint, the system significantly reduces assembly time an essential advantage for professionals working in fast-paced settings. As outlined above, safety is ensured through a comprehensive range of structural components designed to deliver reliable performance, even with large-format LED walls.

Conclusion

The VMB LWS LED Wall Support represents a modern, streamlined, and highly professional solution for floor-mounted LED wall installations. Its modular architecture, universal compatibility, and robust construction make it a valuable asset for rental companies, production service providers, and installers working across museums, trade shows, and corporate environments that require dependable, easily configurable structures.

A system engineered to simplify workflow, reduce installation time, and deliver consistent, high-quality results in any application.

Want to learn more?

Email us at international@audioeffetti.com

English

English  French

French