In the world of professional lighting and displays, three technologies have become widely established for the creation of LED light sources: SMD, COB and GOB. Each of these offers unique features in terms of image quality, luminous efficiency, durability, resistance to environmental factors, and more. In this article, we will explore the advantages and disadvantages of each one, discovering that the best choice depends on the specific requirements of the intended application.

Let’s begin with SMD technology, which emerged in the late 1980s and revolutionized the electronics industry by reducing the size of components and circuit boards, thus increasing integration density and enabling automated assembly processes. Surface Mounted Device (SMD) technology, which differs from but does not entirely replace the previous Through-Hole Technology (THT), is one of the most widely used in the LED sector as well.

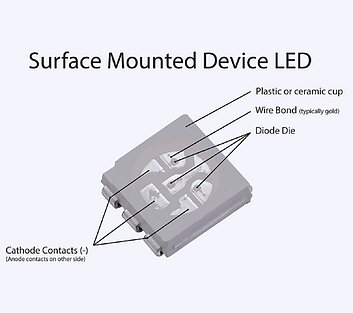

The images below illustrate the structure of an SMD LED and two typical SMD 1515 units, which are frequently used in LED wall modules:

There are countless variations of SMD LEDs, each with its own photometric properties, dimensions and energy efficiency.

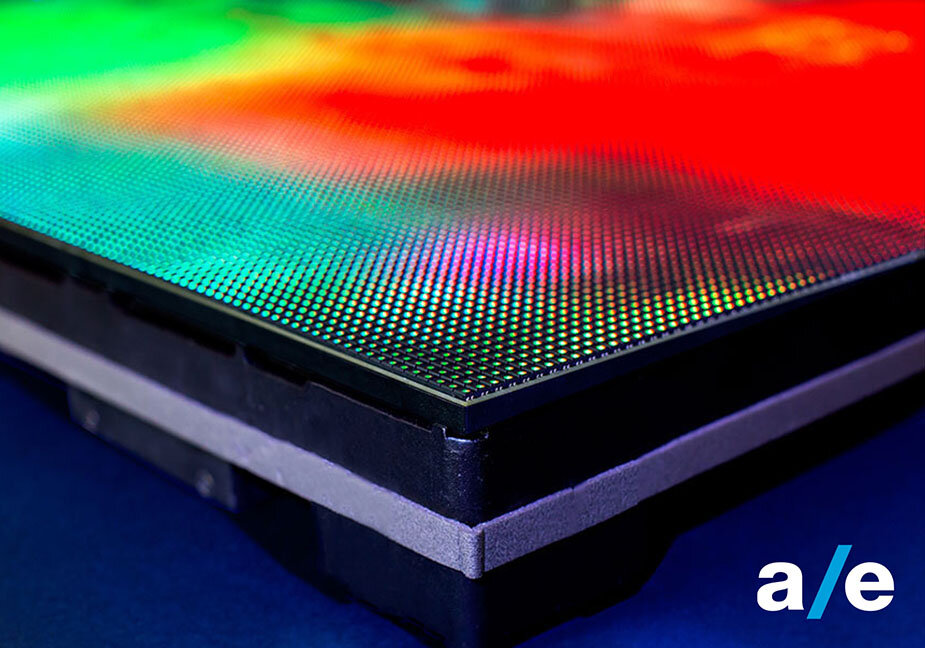

Whether used as the light source in projectors, in LED strips, or in the modules of an LED wall panel (as shown in the picture below), RGB LED chips are mounted directly onto a PCB and are therefore visible on its surface.

Examples of AE products based on this technology include the Mac Mah Beam-Line, which uses 12 Halo RGB 3-in-1 SMD LEDs, the Contest SMARTTAPE3020 pixel ribbon, and the new EGO Display P2.5 front LED display fixed aluminum panel.

This technology offers good brightness, a wide beam angle (around 120°), and easy maintenance, as individual LEDs can be replaced in case of failure. On the downside, the surface remains exposed and thus more vulnerable, with less protection against impacts, scratches, moisture, and dust.

Now let’s move on to COB technology (Chip On Board), which represents an evolution of SMD and began gaining traction in the early 2000s, mainly to improve the reliability of the devices incorporating LEDs. In this case, the LED chips are directly soldered onto the PCB and subsequently coated with a protective resin.

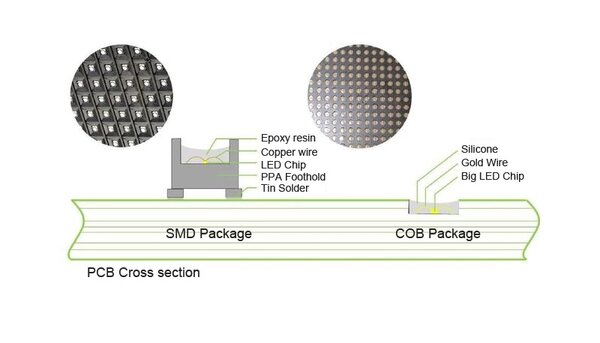

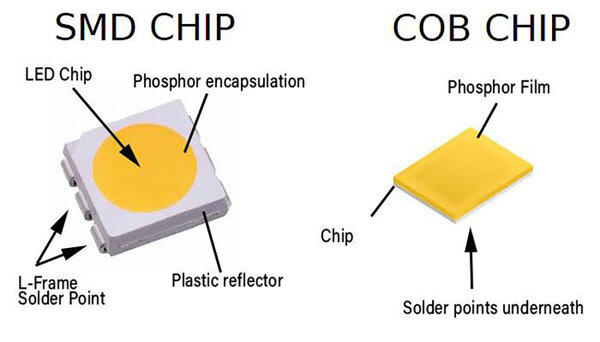

The diagram below shows the difference between an SMD and a COB package:

This method, originally more expensive than SMD but with prices gradually decreasing, creates a uniform surface, as if the LEDs formed a single unit. This improves resistance to external agents and increases pixel density. COB LEDs enable wide viewing light sources, more accurate colors, better thermal dissipation, and reduced PCB footprint.

It’s also worth noting that SMD LEDs require a dedicated circuit for each diode on the chip, while COB allows the use of a single circuit and only two contacts for the entire chip, integrating a virtually unlimited number of diodes. This not only improves efficiency but also simplifies the manufacturing process.

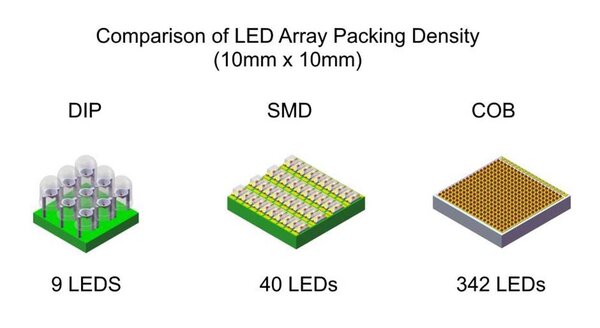

The following image shows, for the same surface area, the difference in integration scale between DIP LEDs (Dual In-line Package) based on the aforementioned THT technology where two rows of pins are inserted into the PCB and soldered on the opposite side and SMD / COB LEDs.

In LED panels, COB technology provides more uniform and higher-quality lighting, effectively reducing moiré effects. Thanks to their even light output, COB LEDs offer a comfortable and prolonged viewing experience, even at close range, with vibrant colors, a wide viewing angle (up to 180°), and excellent image detail due to their ability to support ultra-fine pixel pitches, which translates into superior resolution.

COB LED displays are ideal for security monitoring, control centers, and TV studios, where sharpness and "visual reliability" are critical.

An example of a LED panel using fourth-generation COB technology is the Yes Tech P1.25 Mnano.

Lastly, we turn to GOB technology (Glue-On-Board), which is a variant of SMD that involves applying a transparent resin over the entire surface of the LED module. This protective layer improves resistance to impact and humidity, making the panels more durable and suitable for installations in harsh environments.

Moreover, compared to traditional SMD modules, GOB modules are less prone to damage during transport and installation, making them an ideal choice for mobile applications and digital stage designs.

Thanks to these features, GOB technology is particularly well-suited for flexible screens, such as the EGO Display EasyROLL kit-P2.6-1X2 and flat panels with very fine pixel pitch (< 1.5 mm).

In conclusion, the choice between SMD, COB and GOB depends on the specific needs of the application. If you're looking for a cost-effective and easily serviceable solution, SMD is the ideal choice. For environments exposed to physical contact and high-risk conditions, COB offers maximum protection and enables ultra-fine pixel pitches. Finally, GOB represents a balanced compromise between the two, providing good durability without sacrificing brightness. Both COB and GOB currently offer more robust solutions than SMD in terms of accidental damage resistance. However, they remain extremely difficult to repair, which is why, in certain cases, panels based on these two technologies are (almost) to be considered “disposable”.

The table below outlines the pros and cons of each technology:

|

Technology |

Advantages |

Disadvantages |

|

SMD |

√ Good resolution thanks to reduced pixel pitch √ Easy replacement of damaged LEDs √ High luminous efficiency (up to 150 lm/W) |

√ Exposed surface, vulnerable to impacts and dust √ Lower protection against moisture and scratches |

|

COB |

√ Ultra-smooth and compact surface √ Greater protection against impacts, dust and moisture √ IP68 protection possible ideal for exposed environments √ Capable of achieving very high resolutions |

√ Higher costs compared to SMD √ More complex maintenance (chips not individually accessible) √ Slightly lower brightness at equal power |

|

GOB |

√ Greater durability and resistance compared to SMD √ Smooth and robust surface √ Ideal for high-traffic environments or rental applications |

√ Slight brightness loss due to the resin layer √ More complex repairs in case of localized failures |

Wanto to learn more?

Email us at international@audioeffetti.it

English

English  French

French