From choosing the optimal location to preparing the wall and supporting structure, from cabling to maintenance, this is a practical step-by-step guide to installing a LED wall safely and to the highest professional standards.

A LED wall is not simply a large display created by assembling individual cabinets; rather, it is a visual element that redefines and enhances the space in which it is installed, becoming an integral part of the architecture when designed for permanent installations.

To meet professional expectations, installation must be carefully planned and executed with engineering precision and close attention to detail. Simply aligning a series of panels is not enough. A comprehensive approach is required from the outset one that takes into account the surrounding environment, the design of the supporting structure, safety requirements, and long-term maintenance accessibility.

The preliminary planning phase

A thorough design and planning phase is the foundation for achieving the best possible results once installation is complete. Before any work begins, project objectives must be clearly defined: What will be the primary use of the LED wall? What type of content will it display? In what environment will it be installed?

A LED wall designed to display still images or informational text has different requirements than one intended for high-resolution video or immersive content.

The first step is selecting the appropriate pixel pitch. The closer the audience is to the screen, the more necessary a fine pixel pitch becomes (such as the EGO Display EasyCOB G2-P1.5). In larger indoor venues or outdoor environments, where viewing distances are greater, higher pixel pitch values can be chosen, prioritizing other factors such as brightness and resistance to weather conditions.

Planning, however, goes beyond choosing the most suitable LED panels to achieve specific visual performance. It also involves a careful evaluation of the installation environment. Natural and artificial lighting conditions, potential reflections, and, especially for outdoor installations climatic variables such as rain, wind, and temperature fluctuations must all be considered. These elements influence the selection of appropriate protective measures and required certifications.

At the same time, budget and technical constraints should be defined from the outset. A LED wall represents a long-term investment that must balance image quality, durability, and operating costs.

Finally, preliminary planning must include a logistical assessment: access routes for transporting modules, availability of electrical power, cable routing, and dedicated maintenance areas. Only by addressing these aspects systematically can installers ensure a smooth installation process and achieve a final result that is not only visually flawless, but also functional and reliable over time.

Choosing the installation location

The placement of a LED wall is a key factor that directly influences both the quality of the viewing experience and the overall functionality of the installation. For this reason, its position must be carefully planned in relation to the audience, the surrounding environment, and maintenance requirements.

First and foremost, uniform visibility must be ensured. Unfavorable viewing angles and shadowed areas should be avoided. Ideally, the display should be installed in a location that allows all viewers to perceive the image with the same level of clarity.

Beyond visual performance, as mentioned earlier, the installation location must also take into account practical aspects related to setup. This includes easy access to cabling and power sources, with orderly and secure routing that does not interfere with other building systems, such as fire alarms or thermostats. Ease of maintenance is equally important, which means avoiding locations that are difficult to access.

Finally, for permanent installations, the selected position should integrate as much as possible with the overall design and architecture of the space. In live events or temporary outdoor installations, priority shifts to ensuring maximum visibility and resistance to weather conditions. In any case, location is never a secondary detail—just like the shape of the display itself.

Structure and support

The supporting structure of a LED wall is an equally critical element when it comes to permanent installations. It can be considered the true “skeleton” of the display: when carefully designed, it ensures that the LED wall maintains its safety and functionality over time, turning it into a reliable and long-lasting investment.

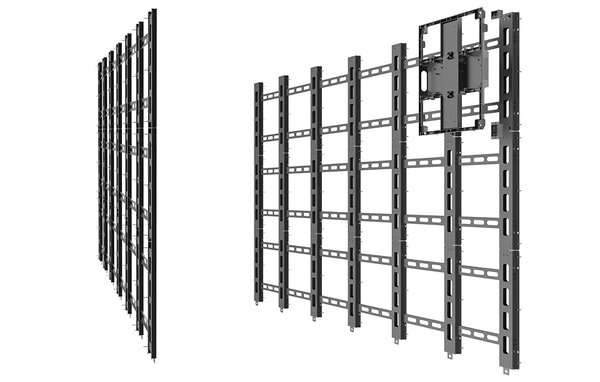

In this context, the use of steel profiles represents an increasingly common and reliable solution. When properly sized and securely fixed to the wall or to a supporting framework, these metal components ensure stability and precise cabinet alignment.

The choice of steel profiles is far from random: steel provides rigidity and structural strength, preventing deformations that could compromise the visual continuity of the LED wall, while also remaining cost-effective. In addition, the modular nature of these profiles allows the structure to be adapted to different sizes and configurations, making the installation scalable and customizable.

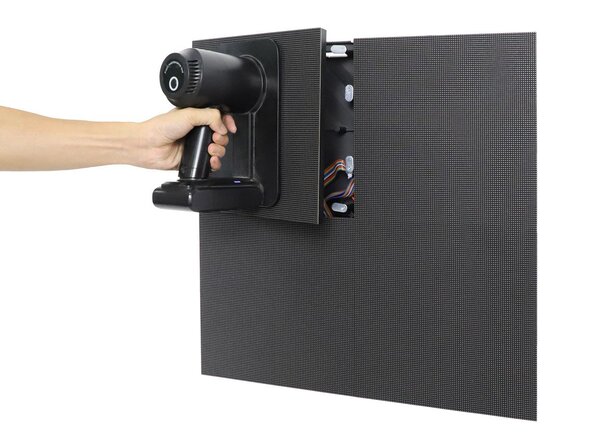

Another noteworthy feature of modern installations is the use of integrated magnetic alignment systems within the cabinets, as found in products such as the EGO Display Easy HP and EGO Display EasyPRO.

The combination of steel profiles and magnetic alignment systems makes it possible to achieve a seamless, perfectly level, and highly stable surface. Thanks to these solutions, the cabinets can be installed and removed extremely quickly, attaching precisely to the metal structure without the need for screws or complex fastening systems. This not only speeds up the installation process, but also simplifies maintenance: a faulty cabinet can be removed and replaced in just a few minutes, minimizing downtime.

In this context, aluminum despite its significantly lower weight cannot be used, as it is not a ferromagnetic material (meaning the magnetic pins on the cabinets would not adhere to it) and is also considerably more expensive.

Regardless of whether simple steel profiles or dedicated mounting brackets are used to support the cabinets, proper attention must be paid to the condition of the wall. Drywall often requires additional reinforcement to ensure perfect flatness and may deteriorate over time without adequate support, potentially causing unsightly gaps. For more solid surfaces such as brick or concrete, it is essential to plan precisely where and how the mounting structures and cable routes will be installed. If the wall is not perfectly smooth, appropriate adjustments can still be made to regulate the mounting depth of the frame.

Finally, never underestimate weight. Adding an extra support layer, such as a plywood panel, is a simple and effective way to provide the wall with more than sufficient strength to safely support the display for years to come.

The installation phase

The installation phase, which includes assembly, leveling and alignment, cabling, calibration, and system configuration, represents the most delicate stage of the entire process. A LED wall does not tolerate alignment or wiring errors, as even the smallest inaccuracy can compromise visual continuity and system stability.

For this reason, the approach must be methodical and rigorous, following a structured procedure that ensures precision and long-term reliability.

The first step is to prepare the cabling. Power and signal lines must be organized in a clean and orderly manner, with dedicated routing paths that prevent tangling and interference. Well-designed cabling not only simplifies future maintenance, but also reduces the risk of malfunctions caused by unstable connections or overheating.

In addition, cable routing must comply with safety regulations, especially in public installations, where protection against overloads and short circuits is essential.

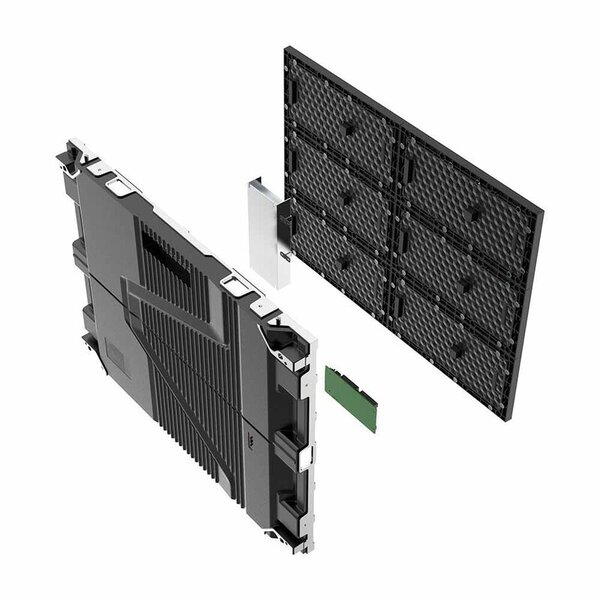

Once the electrical setup is complete, the installation of the cabinets can begin.

After assembling the supporting structure and securing it to the wall, the cabinets are positioned and first fastened to each other, then attached to the supporting framework. Installation typically starts from the center and progresses along the row before moving on to the upper row.

Precision is essential at this stage: each cabinet must be perfectly leveled and aligned to create a seamless, perfectly flat surface. It is crucial to verify overall planarity using appropriate measuring tools, ensuring consistency across the entire display and avoiding micro-variations that could become visible over time.

Once power and signal cabling is complete, the LED modules are installed on the cabinets (when the LED wall is mounted directly on the wall), paying close attention to orientation—unless systems such as the EGO Display EasyFLEX-P2.5-100 are used. The perimeter frame is then fitted to conceal the outer edges of the supporting structure.

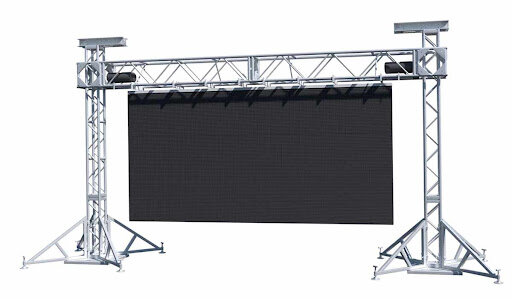

For rental LED walls, such as the Yes Tech P2.9 MG9, or for semi-permanent installations, the procedure is slightly different, as rear access is usually available. In these cases, the LED wall can be floor-mounted, with the base resting fully on the ground—an optimal solution for television studios—or suspended from a horizontal truss, which can be raised using two lifts and positioned as required. This setup is particularly suitable for trade shows, presentations, and similar events.

As a result, supporting structures vary depending on whether the system is intended for permanent wall-mounted installations or for rental and touring applications.

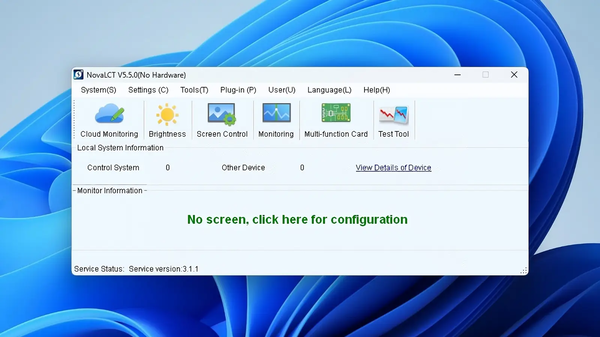

Once installation is complete, preliminary testing can begin. Each cabinet must be powered on and inspected individually, checking for correct brightness levels, color accuracy, and the absence of defective pixels. The entire display is then calibrated to ensure uniform color and brightness across the full surface.

This calibration phase is critical: a properly installed LED wall must deliver a perfectly consistent image, with no perceptible variations between individual modules. Finally, content synchronization tests are performed to verify that video and graphics are played back without delays or misalignment.

Maintenance

A LED wall is a complex modular system that requires ongoing attention to maintain visual quality and operational reliability over time, especially in environments where it often runs 24/7. Maintenance and technical support are therefore equally critical aspects often underestimated that directly affect the lifespan of the investment and overall customer satisfaction.

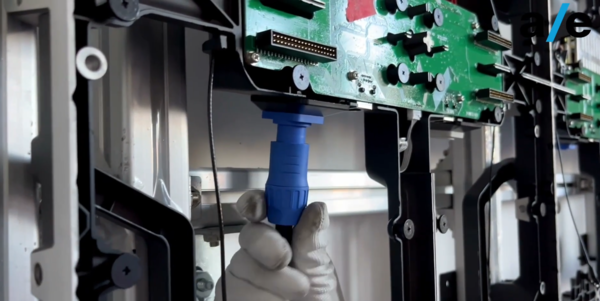

The first key consideration is accessibility. A well-designed LED wall must allow for fast and safe servicing. For this reason, permanent installations typically favor cabinets with front access to the modules and magnetic mounting systems, enabling faulty units to be removed and replaced without dismantling the entire structure. This feature significantly reduces downtime and labor costs, ensuring operational continuity even in demanding environments such as corporate facilities.

Regular cleaning is another essential aspect of maintenance. Dust, residue, and environmental contaminants can negatively affect brightness and color performance, while also increasing the risk of overheating. A proper maintenance plan should include routine cleaning using appropriate tools, avoiding harsh chemicals that could damage the surfaces. At the same time, it is important to monitor pixel performance and promptly identify any defects, allowing corrective action before issues become visible.

Maintenance, however, is not limited to hardware alone. Management software also requires regular updates and inspections. Controllers and calibration systems must be kept up to date to ensure compatibility with new video formats and network protocols. Periodic color and brightness calibration helps maintain consistent image quality over time, preventing variations between modules that could compromise the viewing experience.

Finally, a well-managed LED wall is one where the client has been trained to perform basic routine maintenance tasks. Providing guidance on how to monitor system status, recognize early signs of malfunction, and manage content correctly is an integral part of technical support. This approach reduces reliance on external interventions and increases awareness of the system’s long-term value.

Conclusions

Installing a LED wall is the result of careful planning, informed decision-making, and meticulous attention at every stage—from the supporting structure to final calibration. Simply having a system that “works” is not enough.

The difference between a mediocre installation and one executed to the highest professional standards lies in the details: the precision of alignment, the organization of cabling, the structural solidity supporting the cabinets, ease of maintenance, and consistency in post-installation inspections.

Want to learn more?

Email us at international@audioeffetti.it

English

English  French

French